American

Whiskey:

April

28

& 30,

2011

--

Tennessee

Whiskey

Country

|

No, we didn't make that nickname up. They did. Well, actually the quote (from their Facebook page) was a description of their product as "Hand crafted, small batch ultra-premium booze for badasses", but that's good enough for us. If applied to most every other American spirit we can think of, it would bring up images of rural outlaws (with or without motorcycles). Or maybe Clint Eastwood in The Good, The Bad, and The Ugly.

Actually, Eastwood (in movies, of course, not the actor himself) might be a really good metaphor. While the image of most American spirits might be described in terms of Eastwood's character in the Sergio Leone spaghetti westerns, Corsair Artisan's version of "badass" might better be compared to Eastwood's Dirty Harry.

And just what would you expect from a distillery that was conceived and built by a pair of young men, Darek Bell and Andrew Webber, who were working together on ecological fuel alternatives, when it occurred to Webber that they were putting way too much quality time into developing gasohol and biodiesel products when they could be making fine, truly hand-crafted, artisan alcohol creations instead. Both had prior experience; one with wine, the other with brewing. And both had an appreciation for really good spirits. And both were just crazy enough to do such a thing.

Corsair Artisan makes a wide variety of liquors. Historically they are actually somewhat traditional in nature -- aged bourbon, rye, and malt whiskey, unaged "moonshine" whiskey and rum, spirits flavored with vanilla beans or pumpkin, high-proof distilled spirits (vodka), and gin (they even produce an aged Dutch, or Jenever style of gin). These are not uncommon products; some of them (the gin, for instance) have been around for centuries. Gin (and especially the way they make it) seems to be their specialty, and we'll get to that later, along with their totally unique absinthe. But the grain-based whiskies they distill are very traditional. What is not traditional is the way Corsair Artisan markets these products.

Every distillery has, and promotes, its image. And nearly all mainstream distillers -- especially those that produce bourbon, rye, and malt whiskies -- stress their connection with a past history (often romanticized) of rough 'n' tumble frontiersmen, dressed in buckskin and tending their crude stills in mountain hollows -- or of (even more romanticized) hot-rod moonshiners and bootleggers delivering their spirits in mason jars and milk jugs. Certainly, there really is a lot of that image in the old-line outfits like Beam. In fact, come to think of it, Jim Beam and Brown-Forman might be the only two companies left whose present management actually dates from further back than the 1930s. But even in those post-Prohibition days, the marketing emphasis wasn't on how modern and gleaming and up-to-date their whiskey was made, but rather how much it resembled the old crude spirit that their (in many cases fictional) grandaddys made out in the woods.

Even today's new batch of artisan/craftsman distillers work that same image. Most package their products in old-fashioned style bottles, some intentionally made of quasi-hand-blown or carnival glass, and put home-made-looking labels on them, all in an effort to make them look not just older, but crude and unsophisticated, as well.

Corsair Artisan also makes those kinds of products. And they make them the way artisan distillers would have done so long, long ago. Craftsmanship doesn't change. The difference between a mass-produced item -- clothing, pottery, a lampshade, or spirits -- and an artisan-produced example is obvious to anyone who understands the product. So is the difference between "home-made" and "hand-made". Corsair Artisan's products are hand-made. They are produced by people for whom each step in the process is what they do, what they are proud of, and how they define themselves as professionals.

What Corsair Artisan doesn't do is pretend that they learned this at their grandfather's knee and are carrying on an old tradition handed down through generations of distillers. There is a customer base that appreciates that image, and there is (or at least the folks here hope there is) another customer base who prefer a more modern and sophisticated image.

The bottle that all Corsair spirits come in is modern in appearance. Well, perhaps it's just a little bit '30s art-deco, but certainly fitting for a modern cocktail bar's shelves. And that seems to be their target market -- consumers who prefer sophisticated cocktails made from Corsair's spirits. The image Corsair has fashioned is designed to be appealing to relatively young, vital people who enjoy being a bit trendy, and who demand new and different taste experiences. They tend to be affluent, but not old-line. They are more educated and less rural than those most other distillers imagine as their customers.

The sort that were once derided as “yuppies”, back when we were all deriding folks like Bill Gates and Steve Jobs as “geeks”.

They dress differently, too -- a fact not lost on Bell and Webber. They began this company in 2008 as young, entrepreneurial men themselves. And when they looked for a company image, they chose this graphic, a trio of young men dressed casually in urban evening clothes, looking like they’ve just closed a big deal and are ready to celebrate. It’s a fitting image, because that just what Corsair is… a company of young men, on the move.

And today we are visiting where their spirits come to life.

That’s not really all that easy to do, because “the” distillery actually occupies space in two different states, Kentucky and Tennessee.

Whaaaa?

Well, you see it’s this way… all spirits are distilled from alcohol produced by fermentation. The fermented “mash” can be crushed grapes, sugar molasses, potatoes, or grain. The spirit is separated by means of a still, and that spirit is then often re-distilled to further purify it or to include flavor elements that are just too delicate to have survived the initial process. The results of these distillations are different from one another and, while both can be performed on the same apparatus, having separate equipment extends the range of capabilities. Corsair uses two single-charge pot stills to produce their spirits. At one time, they were both located in Bowling Green, Kentucky. Yes, the same Bowling Green the Everly Brothers once sang about. Unfortunately, both Bell and Webber are, themselves, personally located near Nashville, Tennessee.

That’s a long commute for a job that requires daily participation. But they really had no choice; with two notable exceptions, Tennessee law at the time prohibited the manufacture of distilled spirits generally, even in counties that allowed retail liquor sale. Kentucky state law is less restrictive, so they set up their distillery in Bowling Green… and then they fell in love with the town itself.

Their distillery was (and the Kentucky part of it still is) located in a commercial workspace just off the lovely and peaceful town square. It’s an area where once-old and abandoned storefronts are giving way to new boutique shops, sidewalk cafés, and art galleries. And Corsair, while technically outside the boutique area, is a real participant in promoting the town and it’s own heritage.

But “heritage” is only partially what Corsair is all about. The owners are more focused on producing interesting varieties of cocktail standards along with totally new spirits that will hopefully become popular. Corsair’s product range shows how completely unafraid this company is to produce new products and market them.

And they’ve been pretty successful so far. A partial list of the spirits Corsair makes would include:

-

Artisan Gin, which has won national and world gold medals the last two years running. Also a barrel-aged gin made in the Dutch "oude jenever" style..

-

Spiced Rum (watch out, Captain Morgan; you might be a pirate, but "corsair" means pirate, and Corsair Artisan means business)

-

Absinthe, and not just your everyday green faerie, either; theirs is red! They make it with hibiscus flowers, not food coloring.

-

Vanilla Bean Vodka, made with vodka they distill at low proof, not industrial-grade ethanol. And whole bourbon vanilla beans, too.

-

Several expressions of distilled beer, including an oatmeal stout whiskey, a chocolate porter whiskey, and a hopped stout whiskey (made by using the gin-still to pass only the new whiskey vapors through fresh hops, then aging in charred oak barrels). There is also a distilled Belgian wheat beer infused with wormwood and hops.

-

They produce classic American whiskey as well, including bourbon and rye (both aged and unaged... they call that one "Wry Moon"), a 4-grain whiskey, and something really unusual, a spirit they call Triple Smoke. It's an American single malt whiskey, which makes it very different from bourbon or rye, but it's not really like Scotch, either, exactly. Corsair uses three types of malted barley, each smoked by a different fuel – cherry wood, peat, and beechwood. Then they barrel it in new charred oak, like all bourbons are barreled, but only the latest experimental Scotches are. The peat-smoked portion of the barley does give a "scotchy" flavor, but it's held up on both sides by flavors that are very typically American. If you're familiar with the Del Maguey line of mescals, you'll understand the flavor.

As we said earlier, Corsair uses two copper pot stills for their spirits. At

first, both were located at the distillery in Bowling Green, where they’d also

begun building a nice, modern-looking tasting bar, reminiscent of a cocktail

bar. It is still there, and still in use, but their direction took a major turn

when they found themselves in a situation where they (1) needed more space, (2)

needed more cash flow, and (3) had the opportunity of a lifetime to acquire both

at the same time, along with the state of Tennessee’s permission to do so.

Needless to say, they jumped on it.

Back home in Nashville, about an hour south of Bowling Green, there was a popular brew-pub called Yazoo!, located in the old factory where Marathon cars once were made (note: the Marathon automobile was made in the early 1900s and has no connection with the Checker Marathon, made in Kalamazoo, Michigan from the 1960s to the ‘80s). The Yazoo Brewery had a dedicated and loyal following, so much so, in fact, that they needed to move to a larger venue. The Corsair folks, who were already using their beer facilities to produce the mash for their distillate, bought their existing site, complete with brewing equipment, water and waste hookups, electricity for a production operation, and – not so incidentally – a fully operational brew-pub and potential tasting room (where they continue to serve Yazoo! beer, along with many other craft brews). They moved their primary still and their fermenting tanks there, and continued their secondary fermentation efforts (even more important than the primary in their way of producing spirit) at Bowling Green. All of their bourbon and rye whiskey gets its "doubling" distillation and barreling in the Bowling Green facility. For those into technical issues (and we include ourselves here), that makes their bourbons and ryes "Kentucky" bourbons and ryes. Not Tennessee.

Best of both worlds, indeed.

Nashville, Tennessee...

It is the Nashville location that we visit first. We have picked an un-opportune time for a tour, because a local college has reserved the brew-pub for an alumni celebration. Fortunately for us, we are here before the festivities begin, so there is just enough time to take us around the area that once served as Yazoo's brewery (and whose beer served as the original base for Corsair's earlier distillates).

And here is where things get really weird. We have visited many distilleries, both huge and tiny. And we have seen how some of the best-known brands of American whiskey are actually produced at -- and by -- distilleries that are not normally associated with those brands. It's just the way things are often done in this business. In fact, another Tennessee whiskey producer distilled their own product here before they obtained their own distilling license, and we know of a brand marketed with a very historic name that also uses whiskey distilled here. But what we've never seen before is a distillery site occupied, simultaneously, by two completely different distilleries, each with its own equipment, ingredients, and even its own philosophy about what its product should be.

That is, we've never seen such a thing until now.

In addition to Corsair Artisan, the Tennessee Distilling Company, whose brand is Collier & McKeel, has their equipment and their distilling process here. They don't use the Corsair still (in fact, theirs is over twice the size of Corsair's), they don't use Corsair's fermenting tanks, either. But they work side-by-side with the Corsair folks, in a way that reinforces our fascination with how whiskey people, unlike nearly any other manufacturers we can think of, seem to be able to cooperate and help each other for their mutual benefit, instead of the vicious competition that accountants and stockholders always seem to demand of them.

We will have more -- probably lots more -- to say about Collier

& McKeel later. At this time, their products are available only in a small area

of Tennessee. But they represent only the third whiskey distillery to produce

Tennessee whiskey, using the so-called "Lincoln County" process of mellowing the

distilled spirit through several feet of sugar maple charcoal prior to barreling or

bottling. You will be hearing more about them very soon, we believe.

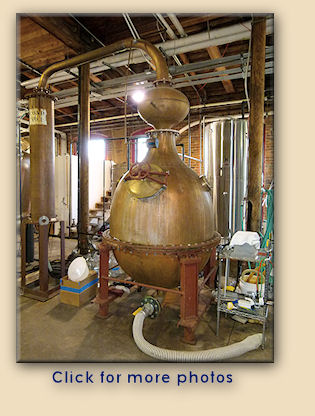

Corsair's fermentation tanks are all stainless steel, and capable of fermenting a variety of mashes. The 240-gallon copper pot still was built around 1920 and managed to survive Prohibition. It was once topped by a tall column leading up to a gin head, but when they moved it here they found it wouldn't fit under the ceiling. They removed it, attaching the gin head directly to where the column's base had been connected. The old section still exists; they've converted it to a coat rack in the brew-pub!

This still produces what is called "low wines" at relatively low proof. That allows more transfer of flavor from whatever they are distilling. In some cases, that's all that's needed, but most of their product is tanked and shipped from here to Kentucky for further work.

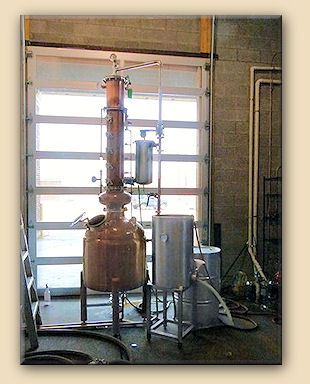

Bowling Green is the location of their finishing still. It is also a beautiful copper pot still, this one with a 4-plate spirit column attached. It also has other features, such as a vapor transfer basket where flowers, herbs, spices, and other ingredients associated with cordials, liqueurs, and other high-quality cocktail spirits can interact with distilled vapors. This is a very artisan method of making these spirits; the less-expensive and more common way is to infuse those ingredients into the spirit and then distill them all together. The cheapest and least-desirable way is to simply add them (as flavorings) to neutral spirits. Needless to say, that's not the way Corsair does it. The still's capacity is only 50 gallons.

Bowling Green, Kentucky...

We arrive at Corsair’s Kentucky location on a brilliantly

sunny day in late April, parking at the town square. The distillery itself, on

an adjacent side street is perhaps among the less inviting-looking we’ve

encountered. Except for two small signs you would never expect a distillery (at

least not a legal one) to be here. It looks like the side entrance to a small

metal-fabrication or rubber goods shop. If you are curious enough to walk up and peek through

the

full length front window, you'll see a beautiful copper pot still, but

otherwise you might think you’ve found the back door. There is a dumpster

standing beside it.

Except for two small signs you would never expect a distillery (at

least not a legal one) to be here. It looks like the side entrance to a small

metal-fabrication or rubber goods shop. If you are curious enough to walk up and peek through

the

full length front window, you'll see a beautiful copper pot still, but

otherwise you might think you’ve found the back door. There is a dumpster

standing beside it.

We enter, and are greeted by Clay, who is the distiller here. He has an assistant with him, Aaron, who is operating the bottling line (as a matter of fact, Aaron is "the bottling line"). The "tour" itself is pretty quick, as there is only a single large room, with part of it set aside for barrels of aging whiskey and other spirits, part for case-goods (they only make a few cases at a time), part for bottling, and part for other production stuff, such as water treatment. The small, but gleaming and modern, still itself, along with its peripheral attachments, is located in a corner at the front of the building, next to the window (which looks like it was once a delivery-truck door). It is here that Corsair's products are converted from raw distillate to the wide range of wonderful liquors they market.

Clay is a great tour guide and spokesman for Corsair Artisan. We asked a lot of questions, and he was able to answer all of them quickly and (we think, having reviewed other folks' tours and information) very accurately. We wish everyone we've encountered in touring distilleries -- especially the large distilleries you'll probably encounter -- would be as informative and knowledgeable.

This was the last stop on our journey through Tennessee and Southern Kentucky. It is a long way home from here, but thanks to XFM and the Comedy Channel, we laugh all the way home. Dinner tonight will be KFC (of course! what did you expect?), and we will again feel happy to know that we've spent some time in the beautiful states of Tennessee and Kentucky.

|

|

|

Story and original photography

©2011 by John F. Lipman. All rights reserved. |

|

The Corsair Artisan

Distilling Company

The Corsair Artisan

Distilling Company