|

--= Click on photo to return

=--

|

|

Mike tells us

about the cypress fermenting tanks.

We even get to stick our fingers in and taste!

--= Click on photo to return

=--

|

|

|

|

These gleaming

copper "safe boxes" are beautiful, and they're not just for

display -- they are functional. The column still can be seen (barely) at the

left.

--= Click on photo to return

=--

|

|

|

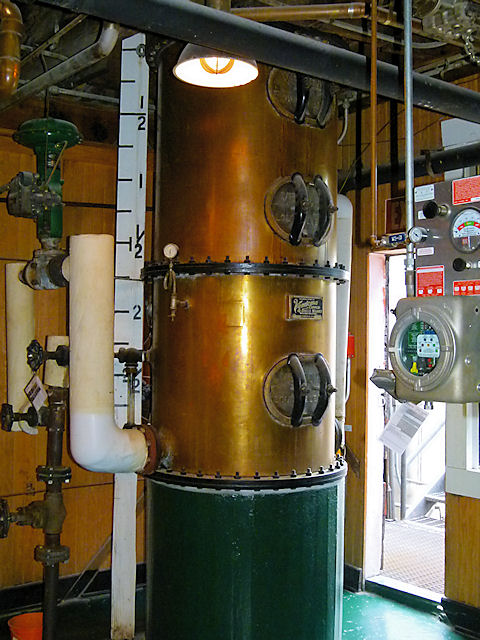

This is the

all-copper 16-plate column still where Maker's Mark bourbon is made.

--= Click on photo to return

=--

|

|

|

The column

still is not in use today, but the corn, wheat, and malt mash

that will be fermented to be distilled is cooking in these tanks.

They (and the room) are very hot.

--= Click on photo to return

=--

|

|

|

Mike uses

these cutaway barrels to show us how they are made and

just what "char" means. Maker's Mark barrels are air-dried for 9 months.

He also shows us what's so revolutionary about the toasted

French oak staves used for Maker's 46.

--= Click on photo to return

=--

|

|

The new bottling line is

immaculate, highly efficient, and massive.

--= Click on photo to return

=-- |

|

Mike explains how the machinery

(which is not in use today) works.

It certainly is a different experience than when we visited before,

weaving our way among the boxes of labels and packaging.

--= Click on photo to return

=-- |

|

Another feature that wasn't

there before: In 1998 it was against the law to

serve samples of distilled liquor. Today, our tour ends (for the adults

anyway)

in this beautiful and modern tasting room, which resembles the Maker's Mark

Lounge in the trendy nightlife section of Louisville. A very pleasant

experience.

--= Click on photo to return

=-- |