American

Spirits

August 31,

2012

The Mountain

Laurel Distilling

Company

Pennsylvania Rye Whiskey is BACK!! |

|

![]()

WE FIRST "MET"

Herman Mihalich by way of an email message he sent to us after reading

our article on the long-defunct

John Gibson’s Sons & Co.

(Moore & Sinnot) distillery in Belle Vernon (or more accurately,

Monessen) Pennsylvania. Shown in the article is the remains of an

iron bridge that had served the distillery until it was closed down in

1923

and the site became the property of the Pittsburgh Steel Company, which

dismantled the whole shebang and built a steel mill. It turns out that

Herman had worked for the steel mill back in the 1970s. He had crossed

that bridge to and from work every day, and the article brought back a ton

of memories for him.

1923

and the site became the property of the Pittsburgh Steel Company, which

dismantled the whole shebang and built a steel mill. It turns out that

Herman had worked for the steel mill back in the 1970s. He had crossed

that bridge to and from work every day, and the article brought back a ton

of memories for him.

But that’s not all…

It seems that Herman grew

up in Monessen, living above his family's bar. They served a lot of rye

whiskey in those days. Steel workers like rye whiskey. Canadian rye,

Pennsylvanian rye (not the same thing, you know). Not so much bourbon.

Pennsylvania rye went away in the 1980s; the last distiller (Michter’s)

closed in 1989.

Today

there is a renewed interest in rye whiskey, and there are many expressions

to be tasted and enjoyed. Most of the major bourbon distillers market rye

whiskey today, but that is the Kentucky style of rye

–

somewhat different from the Pennsylvania/Maryland style, and very different

from Monongahela style. Some have offered rye for years; Wild Turkey’s

rye whiskey was originally Pennsylvania rye, possibly from the same source

as Michter’s

whiskey. And rye whiskey appears to be the product of choice for many of the

new artisan/craft distillers.

Today

there is a renewed interest in rye whiskey, and there are many expressions

to be tasted and enjoyed. Most of the major bourbon distillers market rye

whiskey today, but that is the Kentucky style of rye

–

somewhat different from the Pennsylvania/Maryland style, and very different

from Monongahela style. Some have offered rye for years; Wild Turkey’s

rye whiskey was originally Pennsylvania rye, possibly from the same source

as Michter’s

whiskey. And rye whiskey appears to be the product of choice for many of the

new artisan/craft distillers.

However, no one in Pennsylvania has been distilling, aging, and marketing true East Pennsylvania rye whiskey… until now.

When Herman contacted us, he was a successful chemical engineer (fragrances and food products) with a Master’s degree in business from Wharton. He’d been doing what he was doing for over thirty years. And then he realized that it wasn’t what he really wanted to be doing. What he wanted was, in his own words, to prepare “…a business plan to launch a rye whiskey distillery in PA… I am not quite ready to pull the trigger, but I am quite serious. I should have a 'prototype' product ready in a few months”.

Well,

“a

few months”

turned into a somewhat longer period of time. Herman began working with

teachers at the Michigan State University Artisan Distillers Group to learn

how to mash and distill rye whiskey that would have the characteristics he

wanted it to have.

He

wasn’t

interested in simply making whiskey out of rye grain; that was already being

done. He wanted to make rye whiskey the way it was made in Pennsylvania when

Pennsylvania was the very definition of “rye

whiskey”.

It’s

probably safe say that the instructors ended up learning nearly as much

about what they were doing as Herman did.

He

wasn’t

interested in simply making whiskey out of rye grain; that was already being

done. He wanted to make rye whiskey the way it was made in Pennsylvania when

Pennsylvania was the very definition of “rye

whiskey”.

It’s

probably safe say that the instructors ended up learning nearly as much

about what they were doing as Herman did.

When he had successfully learned the existing process and adapted his own ideas to produce small-scale test batches using the team's pilot facility, Herman’s next step was to upscale to a full-sized distillery. Using his business acumen, he obtained financial backing through partners and investors such as would provide for the costs of going into full production.

Among those investors was John Cooper, who also became Herman's business partner in a much more hands-on way. The development of Mountain Laurel Distillery owes nearly as much to Cooper as it does to Mihalich, both from the outset and in an ongoing way. Dad's Hat is not (ordinarily) a "single barrel" product (although there is talk of releasing some "honey barrels" in that format later); it's consistency results from selecting which barrels to "marry" into the final product. Herman credits John's experienced whiskey palette with the ability to do that important step, and that defines what Dad's Hat ultimately tastes like.

Working

together, they obtained a

suitable location, ordered the proper equipment, and set up what would

become a fully-functional distillery business

–

of which Herman would be the master distiller and John the chief

blender/bottler. This idea runs contrary to the

way many artisan distillers approach the challenge of beginning a

distillery. Often, they are younger people, with less real-life experience,

who just want to make whiskey

– and have the

skill to do so. They may become excellent distillers, but whiskey-making

skills are not enough; they need (and too often don’t

possess) the skills to become business entrepreneurs as well.

Herman is a man with a plan. A very well-thought-out plan that comes from his training and his own talent, both as a business developer and as a distiller who knows what he wants to do and knows what it takes to get that done. Our correspondence began over the history of the Gibson distillery and continued all through the development of Mountain Laurel Spirits.

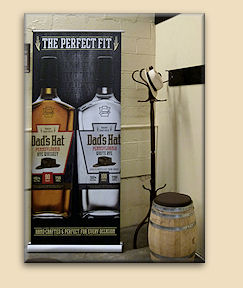

That is the actual name of the distillery company, and it's the name you will find listed on the label as the distiller and bottler of their rye whiskey. But the brand itself is called “Dad’s Hat”, and the story of how that name came to be used is both endearing and gives a very good peek into the kind of man this distiller/marketer is. There is no way that either of us could express the following as well as Herman himself (yes, his writing style is a little like my own; at least as I’d LIKE it to be). So here is his story, in his own words, just as it appears on the distillery’s website:

“My Dad wore hats.

Real hats. The kind you only see in old pictures or movies these days.

He had a lot of hats.

His favorites were Stetson fedoras, handcrafted in Philadelphia.

Before he left the house each day, he’d carefully choose one from the rack and don it. The hat always seemed to fit his mood – or the occasion – perfectly.

My Dad’s gone now. But my mind somehow keeps coming back to those hats. People don’t really wear hats much anymore, I suppose. It’s become an affectation or a fashion statement. But in those days, it was something more. A symbol of optimism. That we cared about quality, polish and finish. A subtle, personal signature. From an era when taking the time to do it the right way mattered.

I founded Dad’s

Hat because I too want to do it the right way. To take up a tradition. To

make something that mattered. The old way. By hand, in small batches.

Using only natural, local ingredients and the most careful methods. Dad’s

Hat is made right here in Pennsylvania, the birthplace of Rye Whiskey, in

honor of my father, who enjoyed rye whiskey and served it at the family’s

tavern; and of that wonderful, optimistic time in America’s

history when we made things and took care to make them well. My heart tells

me that many of us are searching for that spirit again.

Dad’s Hat Rye reflects that same simple, uniquely American personality better than any other whiskey. Crisp. Unfussy. Smooth. Delicious; not lingering or heavy-handed in its finish. Perfect for every occasion. After tasting Dad’s Hat, my hope is that you feel the same.

By the way, I kept those hats. I still wear them. And you know what?

They fit.

Perfectly.”

The distillery itself is located in a rather pretty section of a very working-class neighborhood called Bristol, Pennsylvania. For those of us old enough to remember, it’s where the kids are “sharp as a pistol”. For those visiting the distillery (and it does welcome visitors; the tasting bar has a regular clientele), you’ll pass a few blocks of clean rowhomes on one side of the street and Lions Park and Little League stadium on the other. The park lies on the banks of the Delaware River. Not far from here is the site of the old Philadelphia Pure Rye distillery, long gone but not forgotten. At least not by Herman Michalich, who keeps a framed Hexamer General Survey 1894 blueprint of that facility on the wall of the tasting room.

We first visited Mountain

Laurel a year and a half ago, in July of 2011. At that time the only piece

of equipment in the place was the boiler and steam plant. It had just been

delivered and wasn't even hooked up yet. The rest of the site was filled

with hope and dreams and empty space. We visited Herman again in September, and

things were much more together. Herman had just distilled his first

batch the previous week and he was still making adjustments to compensate for the

difference in scale between what worked on the pilot still and how his

“real”

still operates.

Herman

is very much into detail and documentation. He does nothing

“by

feel”.

At least he says so. Actually, he seems to be very attuned to even minor

variations between what he expects and what he tastes, and is quick to

adjust accordingly. It’s

just that when Herman adjusts something it’s

as if he has to make out a full report to document his actions…

even if he IS the only person who will read the report.

Herman

is very much into detail and documentation. He does nothing

“by

feel”.

At least he says so. Actually, he seems to be very attuned to even minor

variations between what he expects and what he tastes, and is quick to

adjust accordingly. It’s

just that when Herman adjusts something it’s

as if he has to make out a full report to document his actions…

even if he IS the only person who will read the report.

Well, that’s just Herman.

So is the fact that he uses an astounding 95% pure rye grain formula, sourced solely from local Pennsylvania farmers, 80% regular unmalted rye and 15% malted rye. The other 5% is barley malt. Unlike many of the new distillers (and even some of the "old boys", too these days, we suspect) Herman uses no commercial enzymes in producing Dad's Hat rye whiskey.

Mountain Laurel uses a huge 500-gallon Christian Carl still. It is a true pot still, and Herman distills in discrete batches, as was true of nearly all Pennsylvania rye prior to Prohibition. Like other versions of the basic Carl-style pot still, the batch-still part is augmented by a side-column section. However, Mountain Laurel’s side-column is considerably larger than most. In fact, if it were mounted directly above the batch pot it would extend way too high to be contained in the building. It would also then become an auxiliary part of the batch still, instead of a true side column. And Pennsylvania rye, at least Pennsylvania rye made after Prohibition, requires the use of a column still as part of the process. So does Kentucky-style rye, but in distilling that kind of whiskey, the alcohol is stripped FIRST in a column still and THEN re-distilled (doubled) in what amounts to a pot still. Herman does his initial stripping run in the pot still, then uses the column to selectively refine the whiskey.

Does all that really make

a difference?

Well, we’ve tasted many a sample of old Pennsylvania rye, Maryland rye, Monongahela rye, and Kentucky rye, and we’d have to say that it does make such a difference.

It also allows Herman the opportunity to make fine variations in the distilling process. His current aged product, Dad's Hat Pennsylvania Rye Whiskey, is engineered specifically to be aged for 6 months in quarter cask barrels. Because of the way it's made (the mash bill, the fermenting and distilling processes) it is customized to be at its peak potential in that time, without developing the "small-barrel stink" that often occurs when a distiller tries to use standard techniques for specialized maturation conditions. Dad's Hat Pennsylvania White Rye is also available, which is the unaged version for those of us who appreciate the taste of white whiskey.

Herman has also developed an entirely different product for longer-term storage in standard 53-gallon barrels, which will produce an entirely different style of rye whiskey. It uses the same mixture of grains as the current whiskey, but the distillation techniques have been altered to produce whiskey that will greatly benefit from the larger barrels and longer maturation time. That will be labeled as "Pennsylvania Straight Rye Whiskey". Much as we enjoy the current product, we can barely wait for that one to come out.

But I guess we'll just have to.

|

|

|

Story and original photography copyright © 2012 by John F. Lipman. All rights reserved. |

|